Getting the Most from IoT with JDE EnterpriseOne Orchestrator

The Internet of Things provides a phenomenal opportunity for businesses to transform assets into smart users of JD Edwards. However, making that happen can prove challenging. Interfacing physical world assets with the digital world may present unexpected obstacles. At ACBM, we’ve been doing IoT/JDE integration with the Orchestrator from day one. Here are some great use cases that show the value of pairing the Orchestrator with IoT and lessons we’ve learned along the way.

Mobile Asset Management Presented a Perfect IoT Use Case

For companies that rely heavily on assets for production and revenue, availability and usability are critical for success. Being able to monitor usage, location, operating conditions, and other factors provides a massive advantage in keeping assets in working order and extending the life of equipment.

JD Edwards EnterpriseOne has a module in CAM called Condition Based Maintenance that is designed to address this issue. It relies on meter readings to generate work orders for maintenance across three categories (each with its own special considerations):

- Corrective (expensive and results in unnecessary downtime)

- Preventive (requires routine meter readings to trigger PM schedules)

- Predictive (requires real-time monitoring to catch early signs of problems)

Condition Based Maintenance Is Only Helpful If Data Is Current

Manually collecting data to enter into CAM is time consuming and often occurs days or weeks later, allowing problems to fester. A piece of construction equipment out in the field could be overheating. However, when engine temperatures and hours aren’t collected until the asset is returned by the customer, it is too late to prevent serious damage resulting in costly repairs.

In contrast, IoT meter readings are automatically entered directly from assets regardless of location. This improves maintenance and monitoring to reduce unexpected failures and downtime. For rental companies, it also allows billing based on usage, location, and other costs that relate directly to wear and tear on the equipment.

In our talks with Oracle, it became clear that adoption was low for this Condition Based Maintenance module for a simple reason. There was no way for customers to get equipment data into JDE in a timely manner. IoT should be able to solve this problem easily. So why weren’t people leveraging IoT in this space?

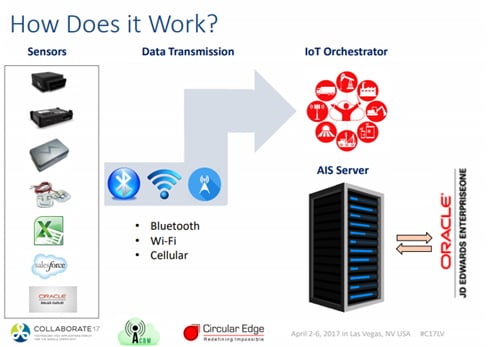

Here’s the basic architecture of an IoT + Orchestrator solution for CAM:

Seems simple right? Looks can be deceiving. Let’s look at what it took to build one in real life.

Building the World’s First Orchestrator-Based IoT Application

Our goal was to see if it was possible to get real-time data from a vehicle into JDE. We started with purchasing low cost retail OBD2 devices that use bluetooth or WiFi. The devices were not durable and they required manual setup and configuration in the field. The device had to be plug and play as well as self-reporting in any conditions to deliver real value. We worked with several manufacturers and ended up selecting a cellular-enabled device that would automatically send data back to JDE. But our work was far from done.

In a vehicle, the odometer is one of the most important metrics for condition based maintenance. Unfortunately, these don’t have a standard code (PID) across vehicles. Even with the same manufacturer and make, a vehicle model’s PID and storage method for this code could be different from one year to the next. This made it very difficult to find a solution that would work on any vehicle to report the odometer.

At first we only found one device manufacturer that would function as needed. We worked with them to customize the firmware, put it on the IoT device, and licensed a separate library of custom odometer PID codes for all vehicles. With this setup, we could now retrieve the true odometer and custom data points in addition to the standard error codes, temperatures, pressures, fuel usage, and countless other data points across all manufacturers and models.

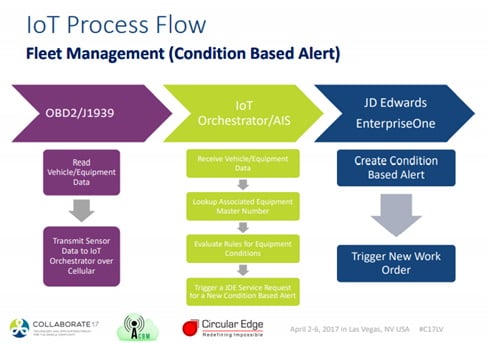

This is how it works:

Want to see ACBM’s IoT Fleet software and all its features in action? Check it out here.

Note: Back when we started creating this IoT solution, there was no Orchestrator studio. We had to build the code by hand in Notepad and copy it into the AIS server. We’re proud to say our original orchestrations still work perfectly today!

Quick Use Case 2: Saving 5000 Hours Per Year with IoT Orchestration

Seminole County in Florida operates hundreds of pieces of equipment across 10 locations. These assets included pumps, blowers, generators, and conveyors that need preventive maintenance based on hours of operation. Every day, an employee at each site was tasked with:

- Walking around to each asset and...

- Reading off the number of hours it had been running then...

- Writing it down on a piece of paper on a clipboard and...

- Giving it to another employee who would then...

- Hand type all the numbers into an Excel spreadsheet then...

- Forward it to an employee at headquarters who would....

- Hand type all the Excel data into JDE using three different screens and…

- Creating a second record for federal government reporting.

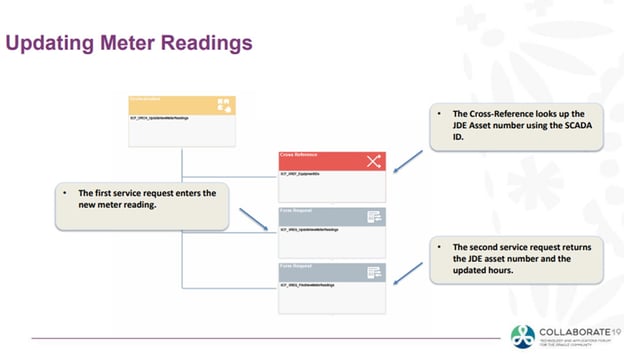

Besides being a massive labor requirement, repeated rekeying of information introduced opportunities for errors. This made it difficult to accurately predict and schedule preventive maintenance. By building a simple IoT integration and orchestration, they can now enter data directly from the equipment into JDE. This project cost less than $5000 and saved 5000 hours per year, delivering huge ROI in record time.

Which JDE IoT Integration Project Will Deliver Value for Your Organization?

The software world and the mechanical world are very different. Physical assets aren’t always designed with connectivity in mind. This can make it tricky to create a successful integration. However, there is absolutely a way to unlock a whole new world of condition based maintenance usage within your CAM using IoT and the Orchestrator. That can be fleet management, asset tracking, or PLC equipment integration right on the shop floor.

ACBM has the experience to design and complete these projects. See more about our Oracle validated IoT Fleet Management solution or contact us about your own integration idea today.